- GST No. 23ACCPP7027Q1Z8

- Send SMS

- Send Email

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Preferred Buyer From

| Location | Worldwide |

The major concern of our organization is to provide only quality approved products to the customers and thus we check each product at all stages. Timely delivery is our forte as we have up-to-date transit facilities and logistic services.

Features :

- No bottle No Capping.

- Faster Tool Less Change Over of Bottle Change Parts.

- Motorized Height adjustment to Eliminate Operators Fatigue.

- Centralized Lubrication.

- Machine conveyor is driven with Bonfiglioli make Variator Drive.

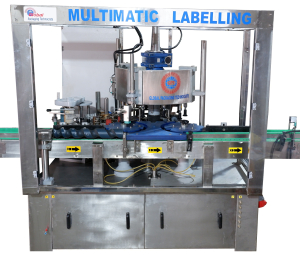

Main Body Structure : The main frame is made of mild steel painted and completely covered with Stainless Steel 304. The machine is made of adjustable feet for the existing production line.

Drive Unit : Main drive motor is equipped with Static controller installed at the main control panel, for variable speed. All gears are made of EN GRADE , synchronized and driven by geared motor. All gears are assembled with leak proof seals. Soft start giving gradual speeds pick up after stopping the machine reaches the stored running output. The height adjustment unit allows handling of various height bottles.

Ropp Cap Tightner :

- On the top of the body the M.S. revolving turret completely lined with stainless steel buffed to bright finish and will be connected to the main gear inside the body.

- The unit will be provided with a the centre column/shaft, a special designed cam carry 10 no’s specially designed ZIGMA ROPP capping heads are mounted, which are made from high carbon high chrome steel precision machined, duly hardened, suitable for threading and sealing for 25 mm size cap of Aluminium.

Automatic Standard Hopper Cap Feeder : The unit will be provided with a disc as per the cap size driven by 1.0 H.P. geared motor. The Caps are sorted out and are finally conveyed to the cap releasing chute and cap shoe.

Sealing Section Operation : The Filled bottles from Filling Section is carried by infeed worm and star of the machine, the bottles pick the caps from the cap shoe of its own on the bottle’s mouth to ensure that caps are properly placed over the neck of the bottles for minimal rejections and sealing heads then tightens caps on the necks of the bottles which ensures proper capping. The bottles are centered exactly below the Capping Head with the help of sealing centre star. The sealed bottles are smoothly transferred on to conveyor by outfeed star.

Details

| Model | 10 Head |

| No. of Head | 10 Capping Head |

| Direction | Left to Right |

| Type of Bottles | Glass Bottles ( As your Sample ) |

| Size of Container | As per Sample |

| Type / size of Caps | ROPP 25 mm ( As your Sample ) |

| Output | Upto 200 BPM |

| Pneumatic Pressure | 5-6 Bars |

| Electrical Connection | 415V , AC , 50 Hz |

| Power Connection | 4 HP , 3 Phase |